Solutions For Cold Chain Control

See how Nova Control delivers verified outcomes across critical cold chain operations. Each use case connects to measurable operational results.

Gate Verification

Verify trailer identity, temperature compliance, and visual condition at facility entry. Reduce gate processing time and eliminate manual checks.

Inputs

- Trailer license plate recognition

- Temperature sensor readings

- Visual condition inspection

- Driver and carrier information

Outputs

- Verified trailer ID match

- Temperature compliance status

- Damage detection alerts

- Automated gate release decision

ROI

Reduce gate processing time by up to 40%; eliminate temperature excursions at entry with automated verification.

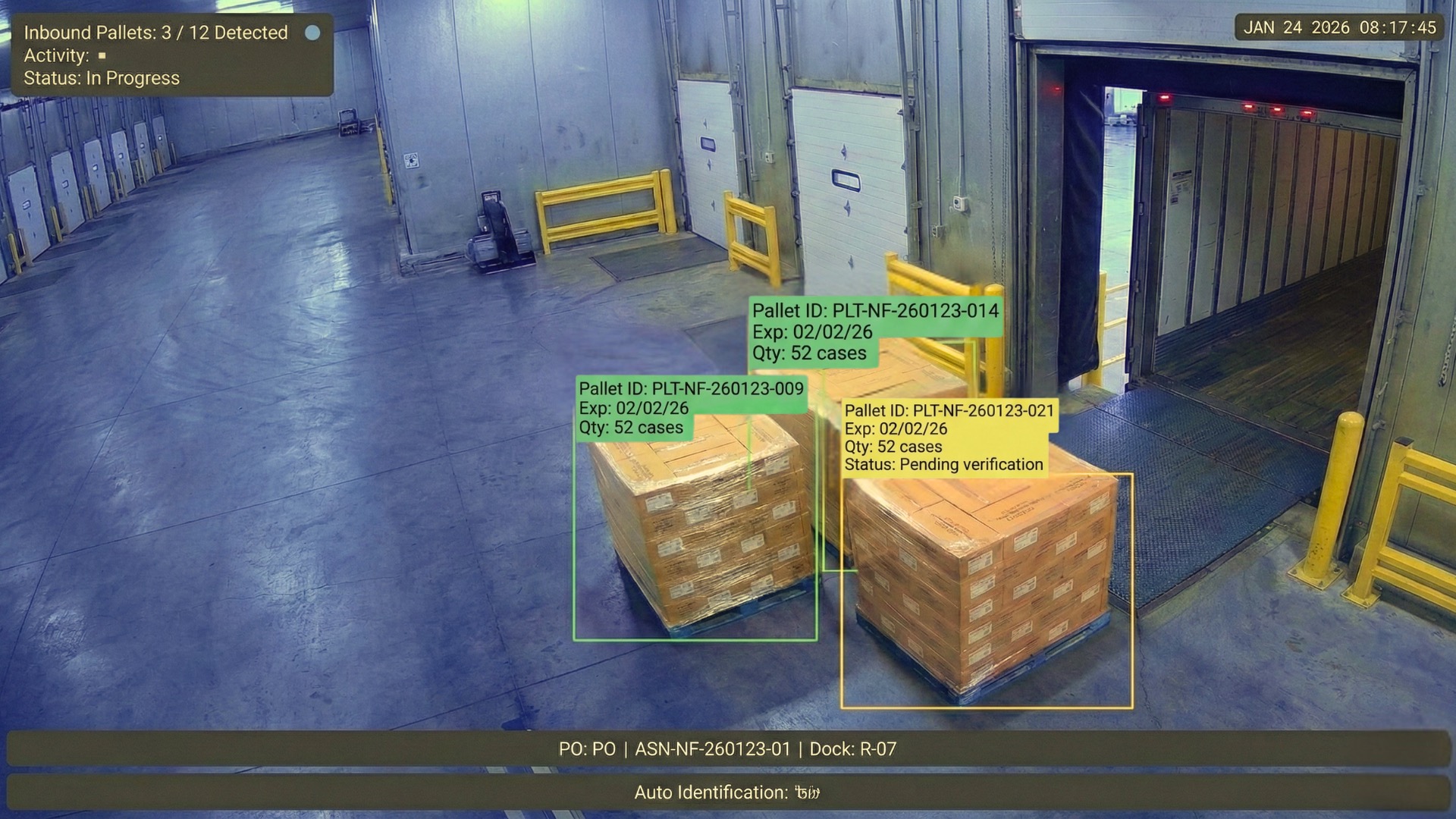

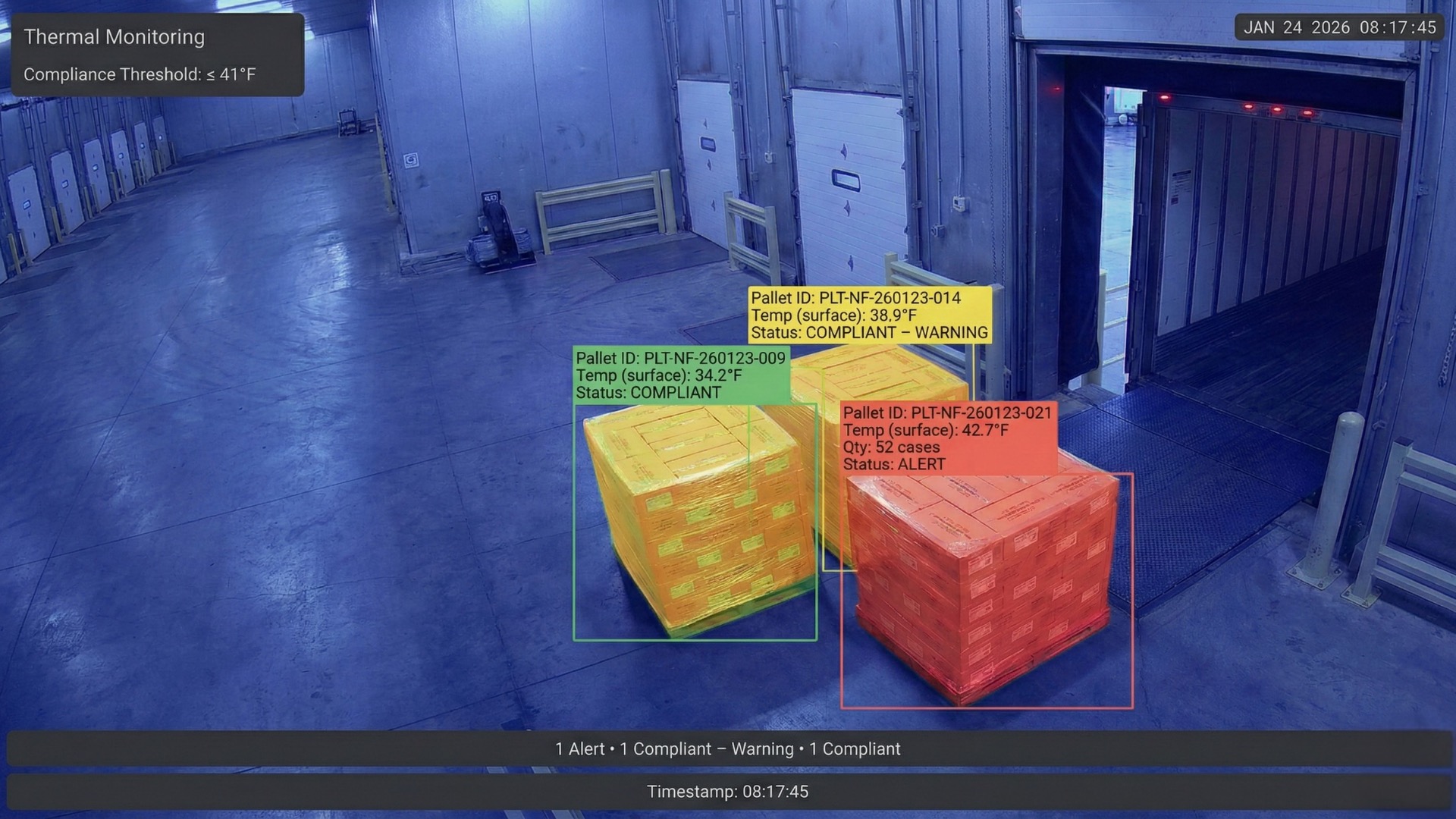

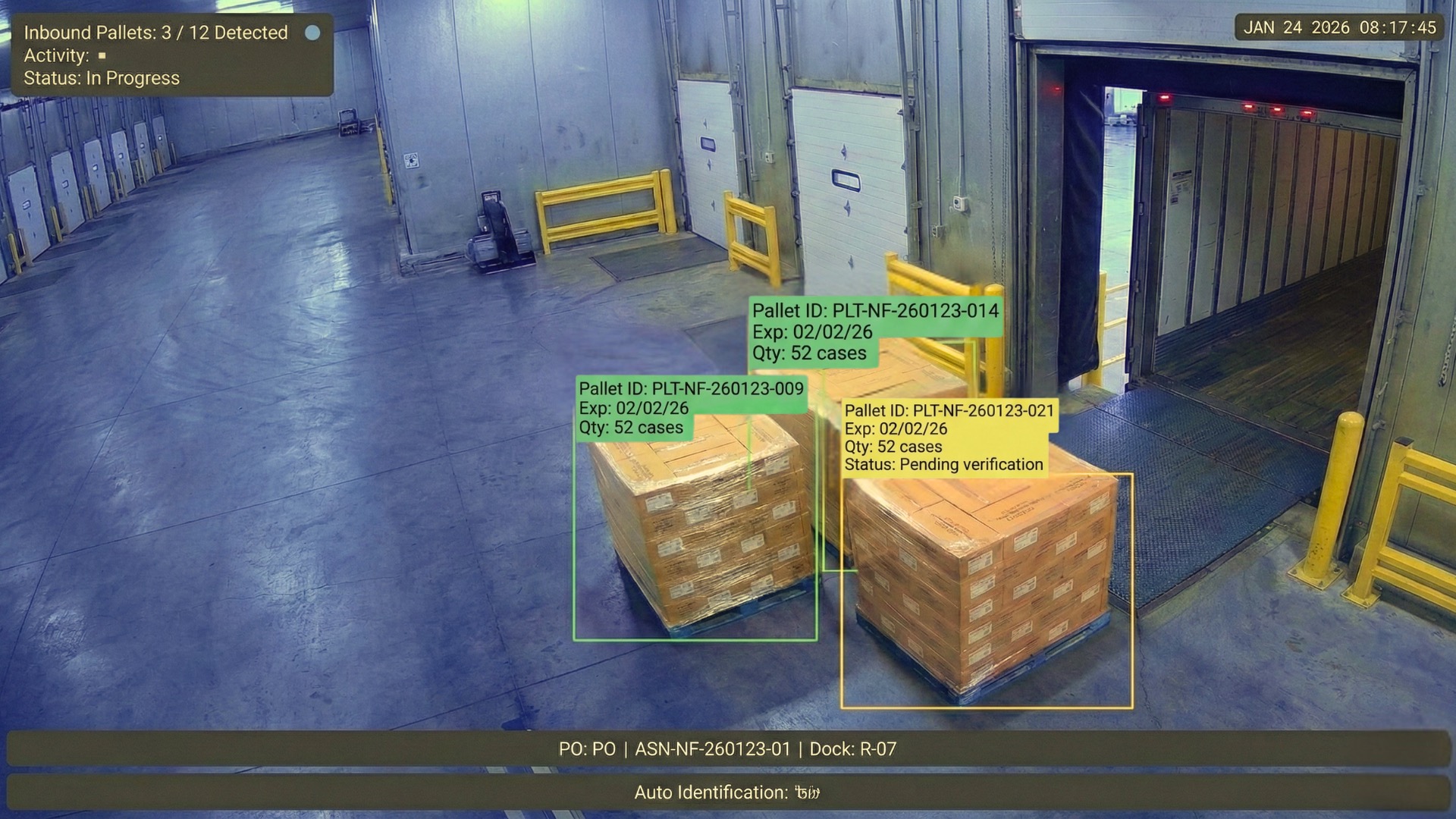

Dock Verification

Monitor temperature during dock operations. Validate product labels and condition. Prevent temperature excursions before they impact product quality.

Inputs

- Thermal imaging at dock

- Product label scanning

- Load condition assessment

- Dock door status

Outputs

- Real-time thermal alerts

- Product validation results

- Load condition verification

- Automated dock assignment

ROI

Zero temperature excursions at dock; up to 35% reduction in product loss with real-time thermal validation.

Load/Unload Condition Verification

Continuous monitoring during handling operations. Automated damage detection and condition verification. Reduce claims and improve quality control.

Inputs

- Visual condition monitoring

- Handling operation tracking

- Product movement data

- Environmental conditions

Outputs

- Real-time damage alerts

- Condition verification reports

- Handling compliance status

- Automated workflow triggers

ROI

100% condition verification coverage; up to 50% reduction in damage claims with automated detection and alerts.

Warehouse Anomaly Detection

Continuous thermal and visual monitoring for equipment failure, theft, environmental anomalies, and security breaches. Real-time alerts with automated response.

Inputs

- Thermal imaging across facility

- Isotherm monitoring

- Motion and access detection

- Equipment status data

Outputs

- Real-time anomaly alerts

- Thermal excursion notifications

- Security incident reports

- Automated response workflows

ROI

Under 5 minute response time to anomalies; up to 30% reduction in product loss from equipment failure with real-time monitoring.